Chapter 4 Geotechnical Engineering: Pile Capacity Estimation#

1. Introduction#

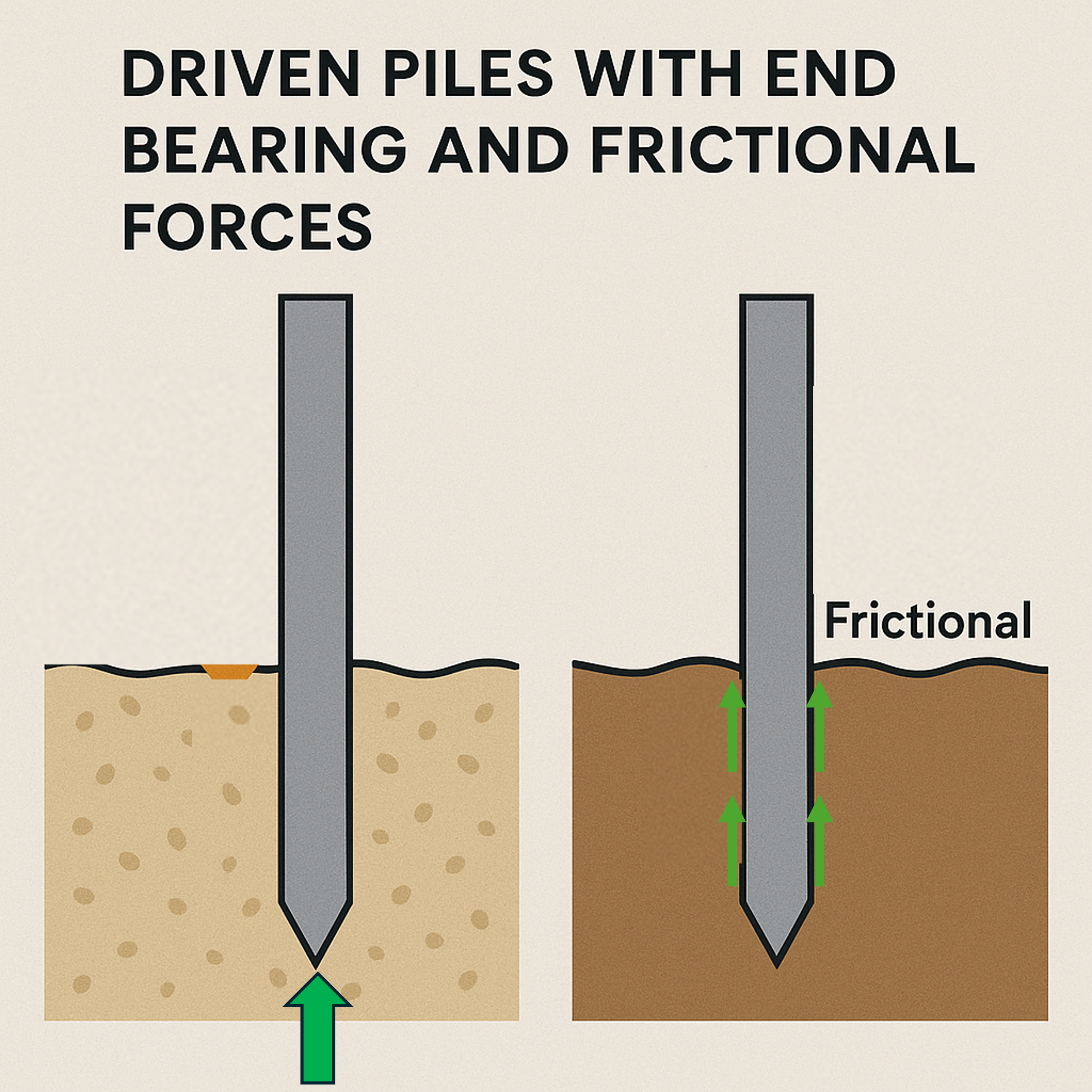

Fig. 23 **Figure 4.9 **: Estimation of ultimate load bearing capacity for pile.#

🧱 Deep Foundations and Pile Load Capacity#

A deep foundation is a structural element that transfers building loads to deeper, more stable soil or rock layers when shallow soils are weak or compressible. Unlike shallow foundations, deep foundations bypass problematic surface layers and rely on end-bearing or skin friction at depth.

🧱 Piles as Deep Foundations#

Piles are long, slender columns made of concrete, steel, or timber that are driven, drilled, or cast into the ground. They are the most common type of deep foundation and are used when:

Soil settlement is excessive

Bearing capacity of surface soil is insufficient

Groundwater or expansive soils complicate shallow foundation design

Structural loads are heavy or concentrated

📐 Types of Pile Load Transfer#

Mechanism |

Description |

|---|---|

End Bearing |

Load is transferred to a firm stratum (e.g., rock) at the pile tip |

Skin Friction |

Load is resisted by friction along the pile shaft in cohesive or granular soils |

Combined |

Most piles rely on both mechanisms depending on soil profile |

🔢 Importance of Estimating Pile Load Capacity#

Accurate estimation of pile load capacity is critical for:

Ensuring structural safety and stability

Preventing excessive settlement or failure

Optimizing pile length, diameter, and material

Complying with design codes and geotechnical standards

Reducing construction costs by avoiding overdesign

📊 Methods for Estimating Pile Capacity#

Method |

Description |

|---|---|

Static Analysis |

Uses soil parameters (cohesion, friction angle, unit weight) to compute end bearing and skin friction |

Dynamic Formulae |

Based on energy of driving hammer (e.g., Engineering News formula) |

Pile Load Tests |

Field tests applying axial load to measure actual capacity |

Empirical Correlations |

Based on SPT, CPT, or other in-situ test data |

Numerical Modeling |

Finite element or limit equilibrium methods for complex soil-structure interaction |

Pile Capacity Estimation Methods: Theory & Equations#

This module explains the geotechnical methods used to estimate axial pile capacity in clay and sandy soils. It includes equations for tip-bearing and friction-bearing piles, and highlights assumptions and applicability.

Soil Types & Resistance Mechanisms#

Soil Type |

Shaft Resistance |

Tip Resistance |

|---|---|---|

Clay |

Adhesion (α·su) |

Undrained bearing (Nc·su) |

Sand |

Friction (β·σ’) |

Effective stress bearing (Nq·σ’) |

Method Descriptions & Equations#

1. Alpha Method (Clay – Shaft Resistance)#

Used to estimate adhesion between pile and cohesive soil:

\( Q_s = \alpha \cdot s_u \cdot P \cdot L \)

Where:

\(( Q_s \)) = shaft resistance (kN)

\(( \alpha \)) = adhesion factor (typically 0.5–0.7)

\(( s_u \)) = undrained shear strength (kPa)

\(( P \)) = pile perimeter (m)

\(( L \)) = embedded length (m)

2. Nc Method (Clay – Tip Resistance)#

Used to estimate the undrained bearing capacity at the pile tip:

\( Q_b = N_c \cdot s_u \cdot A \)

Where:

\(( Q_b \)) = tip resistance (kN)

\(( N_c \)) = bearing capacity factor (≈ 9 for deep foundations)

\(( A \)) = pile tip area (m²)

3. Beta Method (Sand – Shaft Resistance)#

Used to estimate frictional resistance along pile shaft:

\( Q_s = \beta \cdot \sigma' \cdot P \cdot L \)

Where:

\(( \beta \)) = empirical coefficient (≈ 0.3–0.5)

\(( \sigma' \)) = average effective vertical stress (kPa)

\(( P \)) = pile perimeter (m)

\(( L \)) = embedded length (m)

\( \sigma' = \gamma \cdot \frac{L}{2} \)

4. Nq Method (Sand – Tip Resistance)#

Used to estimate bearing capacity at pile tip in granular soils:

\( Q_b = N_q \cdot \gamma \cdot L \cdot A \)

Where:

\(( N_q \)) = bearing capacity factor (≈ 30–50 for dense sand)

\(( \gamma \)) = unit weight of sand (kN/m³)

\(( L \)) = depth to tip (m)

\(( A \)) = pile tip area (m²)

Combined Capacity#

If both shaft and tip resistance are mobilized:

\( Q_{\text{total}} = Q_s + Q_b \)

Assumptions & Applicability#

Alpha method assumes uniform adhesion along shaft in saturated clay.

Beta method assumes effective stress increases linearly with depth.

Nc and Nq methods assume deep foundation conditions and full mobilization of tip resistance.

Group efficiency typically ranges from 0.7–0.9 depending on spacing and interaction.

References#

Several authoritative references provide detailed methodologies and testing procedures for pile design in various geotechnical contexts. These include:

USACE EM 1110-1-1905: Offers foundational guidance on evaluating the bearing capacity of soils, including considerations for pile-supported foundations and subsurface conditions []. FHWA NHI-16-009: A comprehensive manual on the design and construction of driven pile foundations, covering axial and lateral load analysis, installation techniques, and field testing protocols []. API RP 2A: Focuses on offshore pile design for fixed platforms, addressing cyclic loading, scour, and marine geotechnical conditions with industry-standard recommendations [American Petroleum Institute, 2014]. Das (2010): Provides a broad academic treatment of pile foundation principles, including static and dynamic analysis, load testing, and settlement behavior in various soil profiles [Das, 2010]. Together, these resources form a robust foundation for understanding pile design methodologies across terrestrial and offshore environments.

🧠 Conceptual Insight#

Piles are unavoidable in weak or compressible soils —

and their load capacity estimation is the cornerstone of safe and efficient deep foundation design.

💡 These methods provide a reliable starting point for pile design. Final capacity should be verified with site-specific soil data, load tests, and safety factors.

2. Simulation#

🧱 Pile Capacity Calculator – Single and Group Piles#

This tool estimates the load-bearing capacity of piles in clay or sand using three methods:

Friction Only

Tip Only

Combined (Friction + Tip)

It calculates both single pile capacity and group pile capacity, and visualizes the pile geometry.

🔧 Calculation Steps#

Soil Parameters:

For Clay: uses undrained shear strength \(( su \)), adhesion factor \(( \alpha \)), and bearing factor \(( N_c \))

For Sand: uses friction angle \(( \phi \)), lateral earth pressure coefficient \(( \beta \)), unit weight \(( \gamma \)), and bearing factor \(( N_q \))

Single Pile Capacity:

Friction: based on shaft surface area and soil resistance

Tip: based on end-bearing area and soil strength

Combined: sum of both

Group Capacity:

Applies efficiency factor (default 0.85) to account for group interaction

Visualization:

Plots pile geometry with diameter and depth annotations

📊 How to Interpret Inputs#

Input Parameter |

Meaning |

|---|---|

|

Select between Clay or Sand |

|

Choose load transfer mechanism (Friction, Tip, Combined) |

|

Pile diameter in meters |

|

Pile embedment depth in meters |

|

Number of piles in the group |

📋 How to Interpret Outputs#

Output |

Interpretation |

|---|---|

|

Load capacity of one pile based on selected method and soil type |

|

Total capacity of all piles adjusted for group efficiency |

|

Visual representation of pile dimensions and embedment depth |

🧠 Conceptual Insight#

This tool helps engineers evaluate pile design options based on soil type, load mechanism, and group configuration —

supporting safe and efficient deep foundation planning.

# 📌 Run this cell in a Jupyter Notebook

import numpy as np

import matplotlib.pyplot as plt

import ipywidgets as widgets

from IPython.display import display, clear_output

# 📐 Soil parameters

def get_soil_params(soil_type):

if soil_type == 'Clay':

return {'su': 50, 'alpha': 0.6, 'Nc': 9}

elif soil_type == 'Sand':

return {'phi': 35, 'beta': 0.4, 'Nq': 40, 'gamma': 18}

else:

raise ValueError("Unknown soil type")

# 📐 Single pile capacity

def pile_capacity(method, soil_type, D, L):

params = get_soil_params(soil_type)

perimeter = np.pi * D

area_tip = np.pi * (D / 2)**2

if soil_type == 'Clay':

su = params['su']

alpha = params['alpha']

Nc = params['Nc']

Qs = alpha * su * perimeter * L

Qb = Nc * su * area_tip

elif soil_type == 'Sand':

beta = params['beta']

gamma = params['gamma']

Nq = params['Nq']

avg_sigma = gamma * L / 2

Qs = beta * avg_sigma * perimeter * L

Qb = Nq * gamma * L * area_tip

else:

raise ValueError("Invalid soil type")

if method == 'Friction Only':

return Qs

elif method == 'Tip Only':

return Qb

elif method == 'Combined':

return Qs + Qb

else:

raise ValueError("Unknown method")

# 📐 Group pile capacity

def group_capacity(Q_single, n_piles, efficiency=0.85):

return Q_single * n_piles * efficiency

# 📊 Interactive function

def interactive_pile(soil_type, method, D, L, n_piles):

clear_output(wait=True)

Q_single = pile_capacity(method, soil_type, D, L)

Q_group = group_capacity(Q_single, n_piles)

# 📋 Output summary

print(f"🧱 Soil Type: {soil_type}")

print(f"🔧 Method: {method}")

print(f"📐 Pile Diameter: {D:.2f} m")

print(f"📏 Pile Length: {L:.1f} m")

print(f"🔩 Single Pile Capacity: {Q_single:.1f} kN")

print(f"👥 Group Capacity ({n_piles} piles): {Q_group:.1f} kN")

# 📈 Geometry plot

fig, ax = plt.subplots(figsize=(6, 8))

pile_x = [0, D, D, 0, 0]

pile_y = [0, 0, -L, -L, 0]

ax.plot(pile_x, pile_y, color='black', linewidth=2)

ax.fill(pile_x, pile_y, color='lightgray', alpha=0.6)

ax.text(D / 2, -L / 2, f"L = {L:.1f} m", ha='center', va='center', fontsize=10, color='blue')

ax.text(D / 2, 0.2, f"D = {D:.2f} m", ha='center', fontsize=10, color='darkgreen')

ax.set_title('Pile Geometry')

ax.set_xlabel('Diameter (m)')

ax.set_ylabel('Depth (m)')

ax.set_xlim(-0.5, D + 0.5)

ax.set_ylim(-L - 1, 1)

ax.grid(True)

ax.invert_yaxis()

plt.tight_layout()

plt.show()

# 🎚️ Interactive controls

soil_dropdown = widgets.Dropdown(options=['Clay', 'Sand'], value='Clay', description='Soil Type')

method_dropdown = widgets.Dropdown(options=['Friction Only', 'Tip Only', 'Combined'], value='Combined', description='Method')

D_slider = widgets.FloatSlider(value=0.4, min=0.2, max=1.2, step=0.05, description='Diameter (m)')

L_slider = widgets.FloatSlider(value=15.0, min=5.0, max=40.0, step=1.0, description='Length (m)')

n_slider = widgets.IntSlider(value=6, min=1, max=30, step=1, description='No. of Piles')

interactive_plot = widgets.interactive(

interactive_pile,

soil_type=soil_dropdown,

method=method_dropdown,

D=D_slider,

L=L_slider,

n_piles=n_slider

)

display(interactive_plot)

Pile Foundation Capacity Estimation: Project Summary & Interpretation#

Project Summary#

This project estimates the axial capacity of single and group piles in clay and sandy soils using multiple geotechnical methods. It supports:

Tip-bearing and friction-bearing piles

Soil-dependent resistance models (Alpha, Beta, Nc, Nq)

Group pile efficiency

Interactive geometry visualization

Design guidance and applicability assessment

The tool is intended for preliminary design, educational exploration, and comparative analysis of pile behavior under varying soil and geometric conditions.

How to Interpret the Results#

Single Pile Capacity: The estimated load (in kN) that one pile can safely carry based on the selected method and soil type.

Group Capacity: Total capacity for a group of piles, adjusted by an efficiency factor (typically 0.7–0.9) to account for interaction effects.

Geometry Plot: Visualizes pile diameter and embedded length, helping assess slenderness and depth relative to expected soil layers.

Method Comparison#

Method |

Description |

Best For |

|---|---|---|

Friction Only |

Uses shaft resistance only |

Deep clay, long piles |

Tip Only |

Uses end bearing only |

Dense sand, rock layers |

Combined |

Adds shaft + tip resistance |

Most general applications |

Clay: Friction dominates; tip resistance is limited due to low bearing strength.

Sand: Tip resistance can be significant; shaft friction depends on effective stress and depth.

Design Suggestions#

Short piles in clay → Use friction-only method with conservative α values.

Long piles in sand → Use combined method; ensure tip reaches dense strata.

Group piles → Apply efficiency factor (0.7–0.9) to account for reduced capacity due to spacing and stress overlap.

Diameter vs. Length → Larger diameter increases tip area; longer length increases shaft resistance.

Applicability of Pile Foundations#

Foundation Type |

Suitable Conditions |

|---|---|

Friction Piles |

Soft clays, organic soils, deep deposits |

End-Bearing Piles |

Dense sand, gravel, shallow rock |

Group Piles |

Heavy loads, bridge piers, tall buildings |

Driven Piles |

Fast installation, limited access sites |

Bored Piles |

Urban areas, noise-sensitive zones |

References#

USACE EM 1110-1-1905: Bearing Capacity of Soils

FHWA NHI-16-009: Pile Design and Construction

API RP 2A: Offshore Pile Design

Das, B.M. (2010). Principles of Foundation Engineering

3. Self-Assessment#

🧠 Pile Capacity Estimation: Quiz, Conceptual & Reflective Questions#

This module reinforces understanding of axial pile capacity estimation in clay and sand using tip and shaft resistance methods. It supports learning through multiple-choice questions, conceptual prompts, and reflective challenges.

✅ Conceptual Questions#

What does the α factor represent in the shaft resistance equation for clay?

A. Soil unit weight

B. Adhesion between pile and soil

C. Tip bearing capacity

D. Pile diameter

In sandy soils, the β method estimates shaft resistance based on:

A. Undrained shear strength

B. Effective vertical stress

C. Pile spacing

D. Water table depth

Which parameter most directly increases tip resistance in sand?

A. Pile perimeter

B. Pile length

C. Unit weight of soil

D. Adhesion factor

Group pile efficiency accounts for:

A. Increased soil strength

B. Reduced interaction between piles

C. Overlapping stress zones

D. Tip resistance only

Which method combines both shaft and tip resistance?

A. Alpha method

B. Beta method

C. Combined method

D. Nc method

📐 Interpretation#

Why is the average effective stress in sand calculated as ( \gamma \cdot L / 2 )?

What does the perimeter term ( \pi \cdot D ) represent in shaft resistance equations?

How does increasing pile diameter affect tip and shaft resistance differently?

Why is the Nc factor typically set to 9 for deep foundations in clay?

How would you modify the code to include layered soil profiles or variable α/β values?

🔍 Reflective Questions#

How do soil type and pile geometry influence the choice of design method?

Why might engineers use conservative α or β values in preliminary design?

What are the limitations of using empirical methods without site-specific testing?

How does group pile interaction affect load distribution and settlement?

What insights can be gained by interactively adjusting pile length, diameter, and soil type?

💡 Design Insight#

“Pile design is not just about equations—it’s about understanding soil behavior, load paths, and construction constraints. Interactive modeling helps bridge theory and practice.”